Microplate Washers

And Dispensers

Non-contact microplate washers and dispensers fit perfectly into numerous types of labs, specifically labs that focus on cell-based assays, immunoassays, and DNA purification. Microplate washers assist labs in enhancing data quality, improving reproducibility as well as saving time and lowering costs.

Why Our Microplate Washers And Dispensers?

Lowered

cross-contamination

Non-contact liquid dispensing

and washing help limit

cross-contamination, thus

delivering better data.

Highly reproducible

Fewer washing cycles improve reproducibility and precision.

Save valuable

time and money

Save time and money with

fast and automated washing

and dispensing.

Applications

Microplate washers are great for

numerous applications, including

cell-based assays, immunoassays

and DNA purification.

Easy to Use

Eliminate user error with intuitive

and user-friendly software.

What

Is It For?

Biopharmaceutical

Industry

Academic

Institutions

Life Sciences

Startups

Government

Research Facilities

CRO/CDMO

Biopharmaceutical

Industry

Life Sciences

Startups

CRO/CDMO

Academic

Institutions

Government

Research Facilities

Featured

Applications

Cell-based assays

DNA purification

ELISA

Single-cell omics

Plate coating

Single Cell RNA-Sequencing

DNA Purification With

Uniform Results

C.WASH & DNA Purification

Highly Efficient Washing

of Microwell Plates Using

Centrifugal Forces

Improved ELISA workflow

efficiency using automated

plate washing

Product Comparison

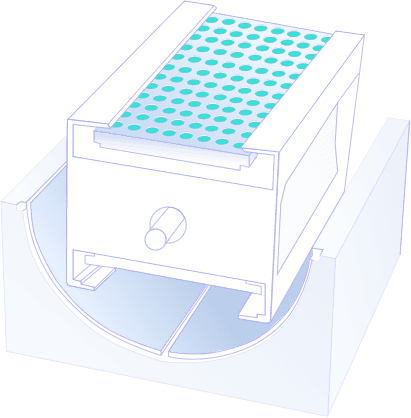

C.WASH PLUS

C.WASH PLUS

C.WASH

C.WASH

G.PURE

G.PURE

Featured Resources

Applications

Frequently Asked Questions (FAQs)

The C.WASH™ has unmatched washing efficiency and reduces the required washing cycles, saving time and resources. Using a non-contact method of dispensing and aspirating liquids reduces contamination and provides better-quality results.

Unlike other needle-based microplate washers, the C.WASH™ is contact-free and eliminates the need for repeat wash cycles due to its small residual volume. With its centrifugal-powered liquid aspiration and the precise dispensing of reagents, the C.WASH™ is a gentler, faster, better way to get high-quality data.

CYTENA’s microplate washer and dispenser comes with multiple compatibility and plate height adjustments to accommodate different types of plates, including 96-, 384-, and 1536-well plates.

The C.WASH has a broad liquid handling range, with the volume of the washing solution dispensed and aspirated varying from microliters to milliliters.

The C.WASH™ has a user-friendly interface and an intuitive design making it quick, convenient, and easy to use.

The simplified maintenance and cleaning of the C.WASH™ saves time and is easy to carry out in the lab. This simplification reduces the likelihood of malfunctions due to improper maintenance, unlike contact-based instruments, which can often clog.

The C.WASH’s fast and automated design enables a complete wash cycle in 96- or 384-well plates in under 1 minute. This speed and the overall reduced washes, thanks to a residual volume of <0.1 uL/well, result in increased throughput and reduced manual labor, which minimizes the risk of human error at critical touchpoints. With the non-contact design reducing contamination and customizable protocols to help with consistency between experiments, the C.WASH™ gives you confidence in the accuracy and reliability of your science.

A microplate washer is a device that uses automated liquid handling to wash the wells of a microplate. The washer removes any excess or unwanted reagents from the wells in preparation for downstream experiments.

A microplate dispenser delivers desired volumes of a given reagent uniformly into each microplate well. The microplate dispenser automates typical manual dispensing and offers the precision and accuracy required for high-quality data outputs.

A microplate washer and dispenser is a dual-action hybrid instrument with all the capabilities of traditional microplate washers and dispensers in one streamlined workflow.

The liquids are distributed through the manifold into the microplate wells for dispensing reagents or washing solutions. This dispensing step is followed by evacuating the liquid using a vacuum or positive pressure for the instrument’s microplate washer capabilities. The washing process can be performed in various modes, including bottom washing, top washing, and both bottom and top washing, and is all entirely contact-free, reducing the risk of carry-over contamination and enhancing washing efficiency.

Using a microplate washer replaces the need for manual, repetitive wash cycles and improves the reproducibility of your results. Removing all unbound or unwanted materials from the wells will ensure accuracy and confidence in your data.

A fully-automated microplate dispenser delivers accurate volumes of your reagent and ensures that each well receives the same volume. The automated microplate dispenser replaces the need for imprecise manual dispensing and improves the reproducibility of your experiments.

A combination microplate washer and dispenser saves you benchtop space and money because you only need one instrument for all your microplate washers and dispenser needs.

A microplate reader detects the light emitted by samples in a plate. These light emissions are measured and quantified by a detector and used as a readout of the biochemical reaction. A microplate washer uses automated liquid handling to wash the wells of a microplate, removing unwanted reagents from its wells.

The enzyme-linked immunosorbent assay (ELISA) is an antibody-based immunoassay that measures specific proteins in a sample. ELISAs are very sensitive to any minor contamination or pipetting inaccuracies. Microplate washers specialized for the application of immunoassays must be accurate. The C.WASH™ non-contact dispensing achieves this by limiting contaminants’ and reagent carryover, reducing the wash cycles required for precision ELISA data.

A microplate washer typically consists of a manifold, a pump, a reservoir, and a user interface. Traditional washers also use an aspirator head, pipette, and liquid handler tips to remove liquid from the wells of a microplate. The C.WASH™ is a non-contact microplate washer that eliminates the need for these parts and reduces your lab’s environmental footprint.