Microplate Agitation Culture System

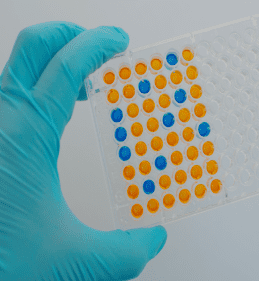

Introducing our cutting-edge microplate agitation culture system - offering adjustable mixing culture in controlled incubation chambers. Compatible with 96- and 24-well plates, this system offers small-scale agitation solution for your everyday cell culture.

Why Our Microplate Agitation Culture System?

Innovative mixing technology

Adjustable and controllable mixing in 96/24-well plates.

Enhanced culture

Homogeneous nutrition distribution and higher oxygen transfer rate.

Optimal incubation

Stable culture environment in multiple incubation chambers with independent parameter controls.

Smallest scale

Mixing in 96/24-well plates, with working volume from 150-1600 µL.

Highest throughput

Run 384 clones/conditions in a single instrument.

Proven versatility

Applicable to CHO, organoids, spheroids, and patient-derived blood cells.

What

Is It For?

Biopharmaceutical

Industry

Academic

Institutions

Life Sciences

Startups

Government

Research Facilities

CRO/CDMO

Biopharmaceutical

Industry

Life Sciences

Startups

CRO/CDMO

Academic

Institutions

Government

Research Facilities

Best-in-class technology. Industry leading results.

Higher cell number

Higher viability

Save time. Save labor. Save cost.

Patented mixing technology

Adjustable mixing pattern for increasing cell growth in your culture.

Field-tested reliability

Proven in real-world conditions for accurate, dependable data.

Featured

Applications

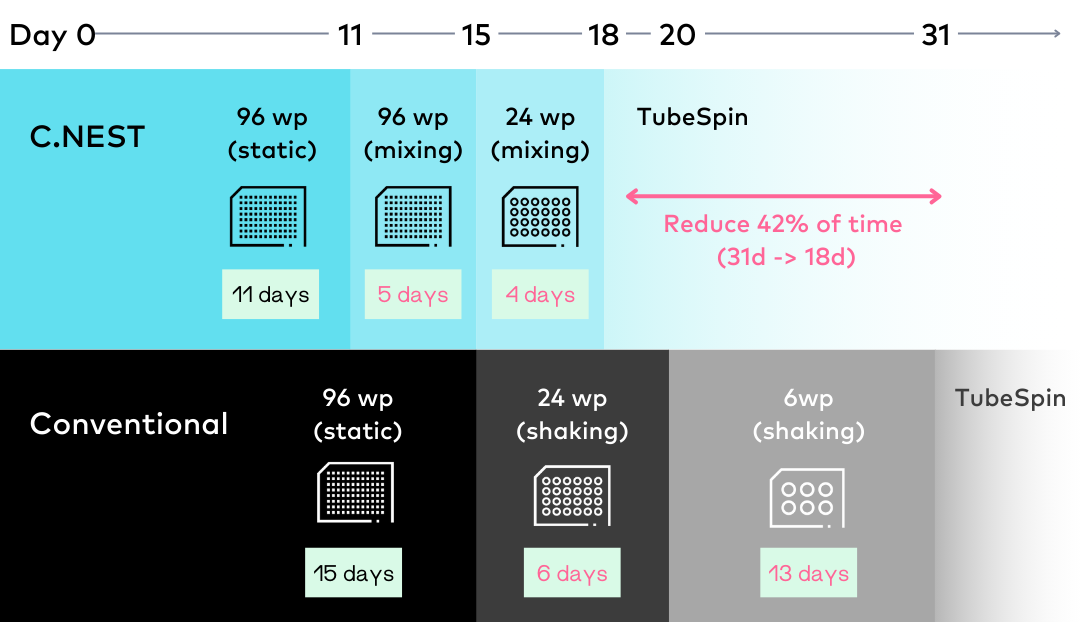

Streamlined cell line development

Faster clone expansion

Faster clone recovery

Organoid/Spheroid culture

Patient-derived blood cell culture

Product Comparison

C.NEST

C.NEST

C.BIRD

C.BIRD

S.NEST

S.NEST

C.NEST

C.NEST

C.BIRD

C.BIRD

Applications

Learn how you can automate research workflows in numerous application areas

Applications

Frequently Asked Questions (FAQs)

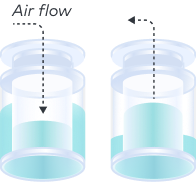

Microplate agitation culture systems use positive and negative air pressure to control fluid flow into and out of each well at different speeds and patterns. This enables reciprocal, pipetting-like mixing, ensures a constant supply of oxygen, and maintains a homogeneous, healthy cell culture environment. Various sensors automatically adjust and regulate conditions, such as temperature and CO₂ levels, to provide an optimal incubation environment for successful cell culture.

These systems reduce time and costs associated with raw materials and labor by:

- Shortening the clone expansion and recovery phase, allowing faster identification of the best clones.

- Optimizing culture conditions more efficiently, accelerating process development.

The working volume of microplate agitation culture systems ranges from 150 to 1600 microliters, enabling small-scale agitation cultures and the screening of clones or expensive reagents before progressing to lab-scale productivity.

Microplate agitation culture systems can cultivate a variety of cell types, from CHO cell lines commonly used in cell line development to patient-derived blood cells and complex spheroids/organoids.

Microplate agitation culture systems are a type of microfluidic system that offers exceptional control over fluid flow, enabling precise manipulation at the microscale. This precision is particularly advantageous for small-scale experimentation and delicate cell cultures.