- PRODUCTS

-

UP.SIGHT™ 2nd GenNEW

Optimized For Proof Of Monoclonality, Colony Tracking, Confluency, & Titer Measurement -

F.SIGHT™ 2.0

Optimized For Rapid Dispensing of Fluorescent Cells -

C.SIGHT™ 2.0

Optimized for Powerful Dispensing of Unlabeled Cells -

B.SIGHT™

Optimized For Rapid Microbial Single-Cell Isolation and Cultivation -

F.SIGHT™ OMICS

Optimized For Single-Cell-Omics -

F.SIGHT™

Optimized For Affordability And Flexibility -

C.SIGHT™

Optimized for Affordable Cell Line Development -

Compare Products

Decide which one is right for you - Help Me Choose

-

UP.SIGHT™ 2nd GenNEW

- APPLICATIONS

- CUSTOMERS

- RESOURCES HUB

- COMPANY

- SHOP

Monoclonal antibodies and the next generation of therapeutic complex molecules

Establish high-performing monoclonal cell lines for mAb production

using modern, future-proof workflows.

using modern, future-proof workflows.

Overview

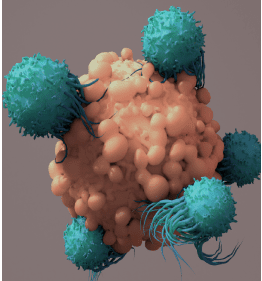

Monoclonal antibodies (mAbs) are a mainstay of modern healthcare. Their application in areas like oncology and immunology has transformed patients’ lives, and their future in clinical care looks even brighter. Bispecific (bsAbs) and tri-specific (triAbs) antibodies broaden target applications and offer more precise treatments that live up to our growing understanding of disease pathways. However, with the increasing complexity of antibody technology, the infrastructure and expertise needed must evolve to meet new challenges. The marketplace is more competitive than ever, requiring researchers to achieve high-quality production while remaining compliant within rapidly shortening timescales.

Effective antibody production relies on high-performing cell lines that conform to validation and traceability standards. CYTENA has been at the forefront of cell line development (CLD) for the last decade. We understand the challenges of developing high producer cell lines for mAb production and the imminent revolution of therapeutic complex molecules. Low seeding efficiency, poor outgrowth, and laborious upscaling delay CLD workflows, which is exacerbated by the need for seamless traceability and proof of monoclonality. Constantly evolving regulatory compliance demands future-proof approaches and technology to ensure ongoing quality and efficacy. CYTENA continues to rise to the demands of modern mAb production by providing best-in-class single cloning technology that gives our clients a significant competitive advantage.

Our state-of-the-art mAb workflow leverages our UP.SIGHT, C.STATION, S.NEST, and F.QUANT instruments to streamline and optimize your research. This workflow generates high-producing cell lines with a probability of clonal derivation of over 99.99%.

Sub-Applications

Monoclonal antibody production

Accelerate your CLD workflows using automated, high-throughput single-cell isolation technology. Establish high-producing clones efficiently, with >99.9 % probability of clonality.

Multispecific-molecule production

Pioneer the production of the next generation bi- and tri-specific molecules with our end-to-end CLD workflow. Streamline your research and minimize risk with robust quality controls and high percentage clonal derivation.

Therapeutic protein production

Generate clonally derived cell lines producing high titers of hard-to-express enhanced fusion proteins.

Research Workflows

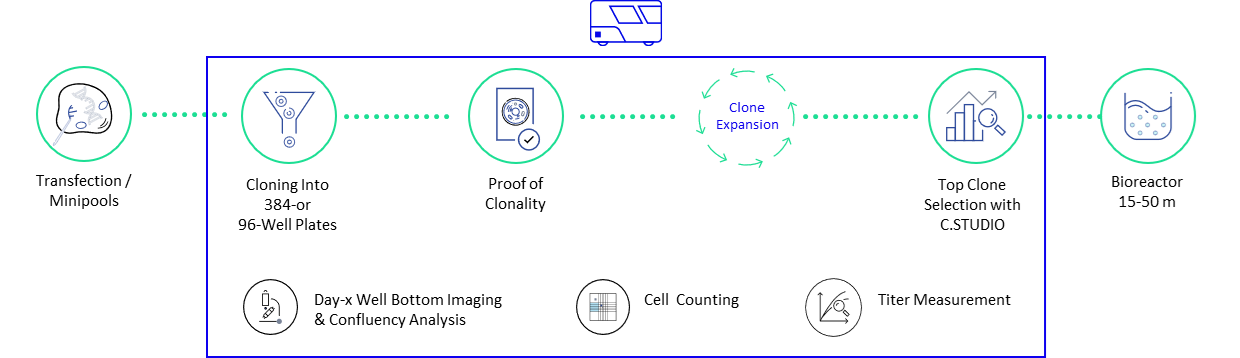

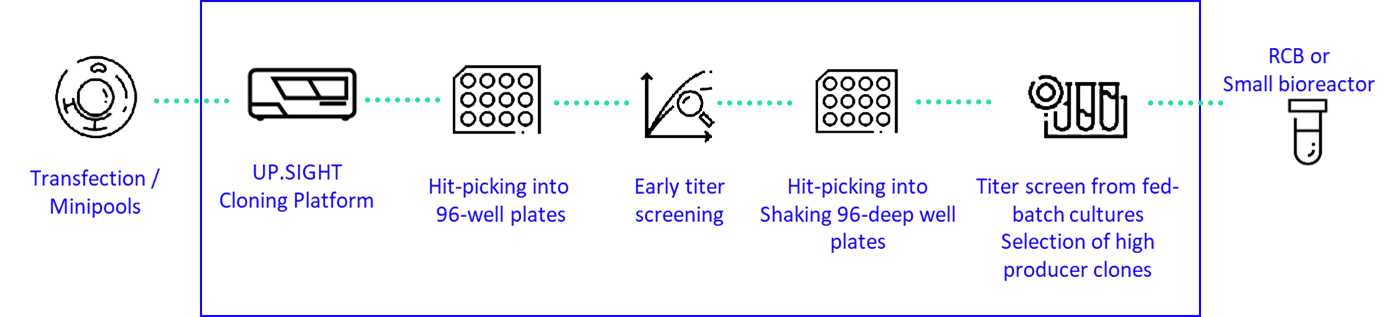

Modern CLD workflow for antibody production using the UP.SIGHT

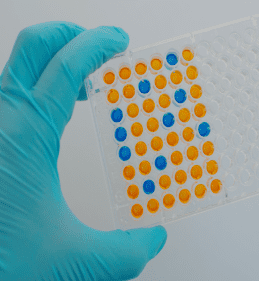

Antibody production starts with the transfection of cell lines, typically suspension CHO cells. Afterward, mini-pools of cells can be screened, or individual cells can be directly seeded for monoclonal propagation. Modern automated high throughput methods utilize 384 well plates for single cell seeding while traditional methods use 96-well plate formats. Proof of clonality of cell populations needs to be rigorously documented to achieve regulatory compliance. Furthermore, cell line growth must be continuously monitored to ensure robust growth and stability. The UP.SIGHT offers delicate single-cell seeding into 96 and 364 well formats and dual imaging capabilities to help ensure monoclonality and monitor clonal growth via C.STUDIO software. Further colony characterization makes use of sensing such as pH and dissolved oxygen under mixing conditions. Before scaling to larger bioreactor volumes, cell line productivity can be assessed via Fc and Fab titter assays like the F.QUANT.

CYTENA supports this workflow by offering the latest technological developments in software and hardware as shown in the following diagram.

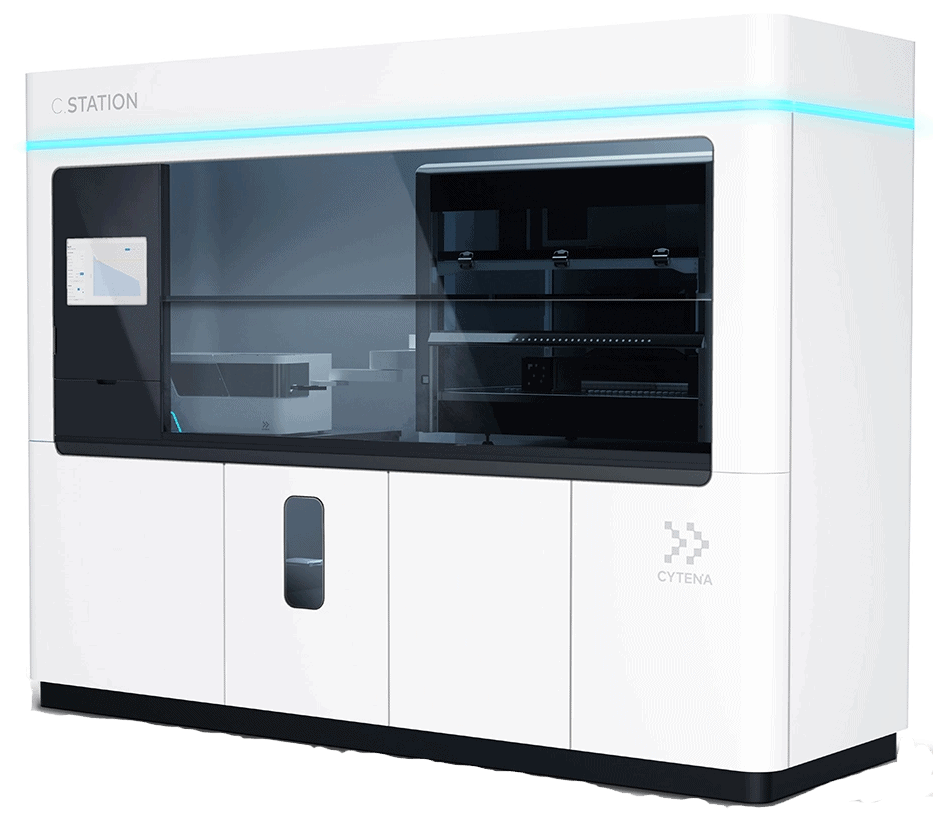

Fully automated Cell Line Development with the C.STATION

The UP.SGHT can be integrated into the fully automated end-to-end CLD workhorse, the C.STATION, amplifying CLD workflow quality and throughput. The C.STATION handles plates via a robotic arm and a liquid handler for all necessary cloning, picking, screening, and incubation steps. Pre-configured workflows mean users avoid the hassle of programming and troubleshooting complex protocols. Automated stations like the C.STATION offer major advantages in throughput and reproducibility making use of 24-hour operation times and parallel project capabilities.

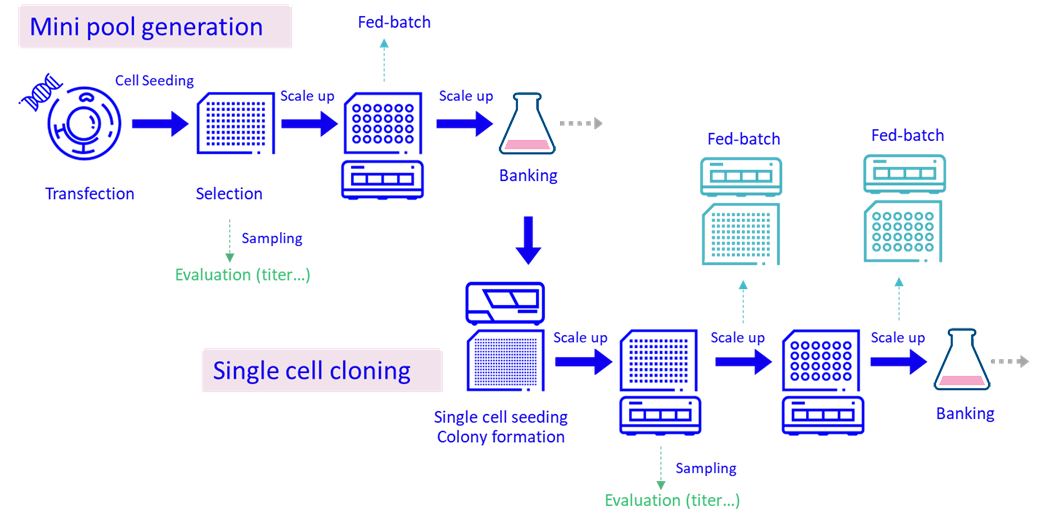

Early suspension cell culture for mini-pool generation and fed-batch processes in CLD workflows

The S.NEST and C.NEST, are microbioreactors capable of cell suspension mixing and generating mini-pools that aid the selection of optimal clones for mAb production. This workflow supports an early feedback process before biobanking, thus providing crucial information on how clones will behave in larger production bioreactors. Approved mini-pools can be cloned using the UP.SIGHT’s single-cell dispensing and dual imaging capabilities to ensure monoclonality and monitor growth. The S.NEST and C.NEST can provide further feedback on clone performance before biobanking.

Featured Resources

Previous

Next